Fly ash bricks have emerged as a sustainable and eco-friendly alternative to traditional clay bricks, gaining traction worldwide. In India, the government has introduced various policies and regulations to encourage the adoption of fly ash bricks and ensure compliance with environmental standards. Here’s a closer look at these policies and how they impact the operations of fly ash brick plants.

The Rise of Fly Ash Bricks in India

With growing concerns over environmental degradation and the depletion of fertile topsoil caused by clay brick manufacturing, fly ash bricks have become an essential part of India’s construction landscape. These bricks are manufactured using waste by-products from thermal power plants, making them an eco-conscious choice.

Government Policies Encouraging Fly Ash Bricks

To support the transition to greener construction materials, the Indian government has implemented several key regulations:

1. Mandatory Use of Fly Ash

The Ministry of Environment, Forest and Climate Change (MoEFCC) has mandated the use of fly ash-based products in construction activities within a 300 km radius of coal or lignite-based thermal power plants. This has significantly boosted the demand for fly ash bricks and encouraged new players to enter the market.

2. Environmental Clearance Norms

Fly ash brick plants must comply with environmental norms related to air and water pollution control. This includes proper dust suppression systems, waste management practices, and emission monitoring to ensure minimal environmental impact.

3. Incentives and Subsidies

Several state governments offer subsidies and financial incentives for setting up fly ash brick manufacturing units. These incentives reduce capital costs and encourage small and medium enterprises to invest in the sector.

4. Bureau of Indian Standards (BIS) Guidelines

The BIS has laid down quality standards for fly ash bricks (IS 12894:2002), ensuring uniformity in production and maintaining construction safety standards.

5. Public Sector Procurement Mandates

Public infrastructure projects are required to use a minimum percentage of fly ash bricks. This move ensures a steady market for manufacturers and promotes sustainable building practices.

Impact on Fly Ash Brick Plants

These regulations have streamlined the fly ash brick industry, making it more organized and quality-driven. Plants are now more focused on innovation, automation, and compliance, leading to better products and lower environmental impact.

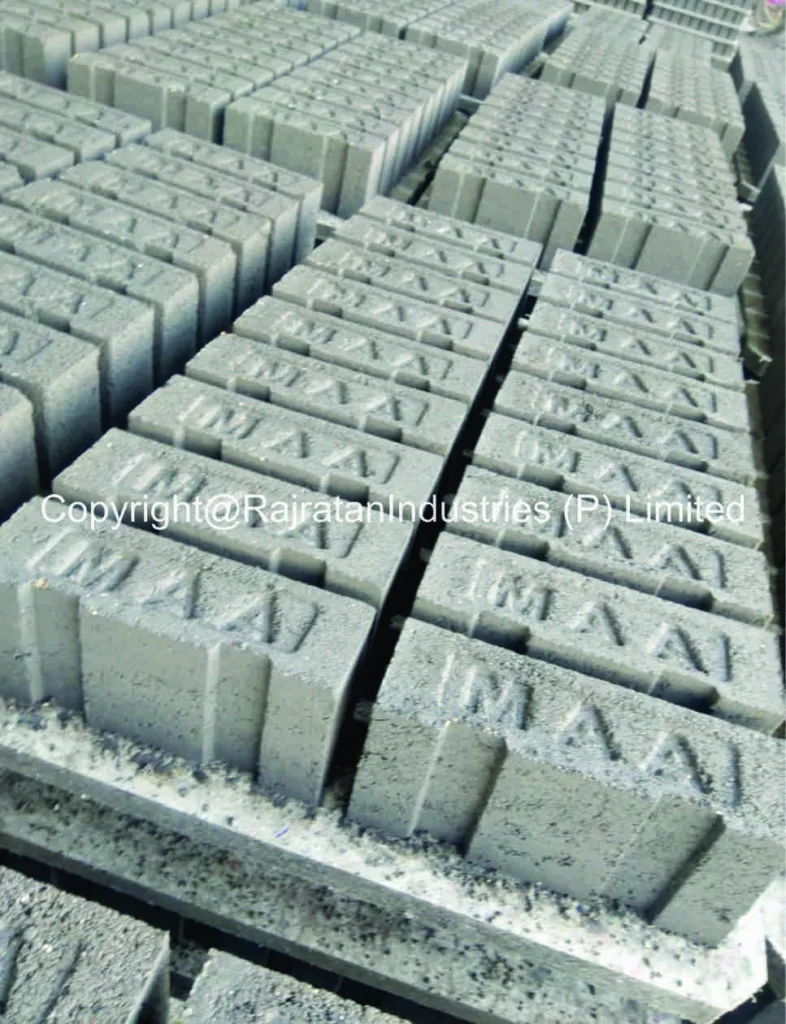

At Rajratan Industries, we are fully aligned with these government initiatives. As India’s trusted manufacturer of fly ash brick, we ensure all our processes meet the highest environmental and quality standards. Our commitment to sustainable manufacturing not only supports national goals but also delivers long-term value to our customers.

Conclusion

The government’s proactive approach through policies and regulations has played a crucial role in shaping the future of fly ash bricks in India. For manufacturers, staying compliant is not just a legal requirement but a strategic advantage in an increasingly eco-conscious market.

To learn more about how we at Rajratan Industries are leading the change, visit our website or contact us today.

Comments on “Understanding Government Policies and Regulations on Fly Ash Brick Plants in India”